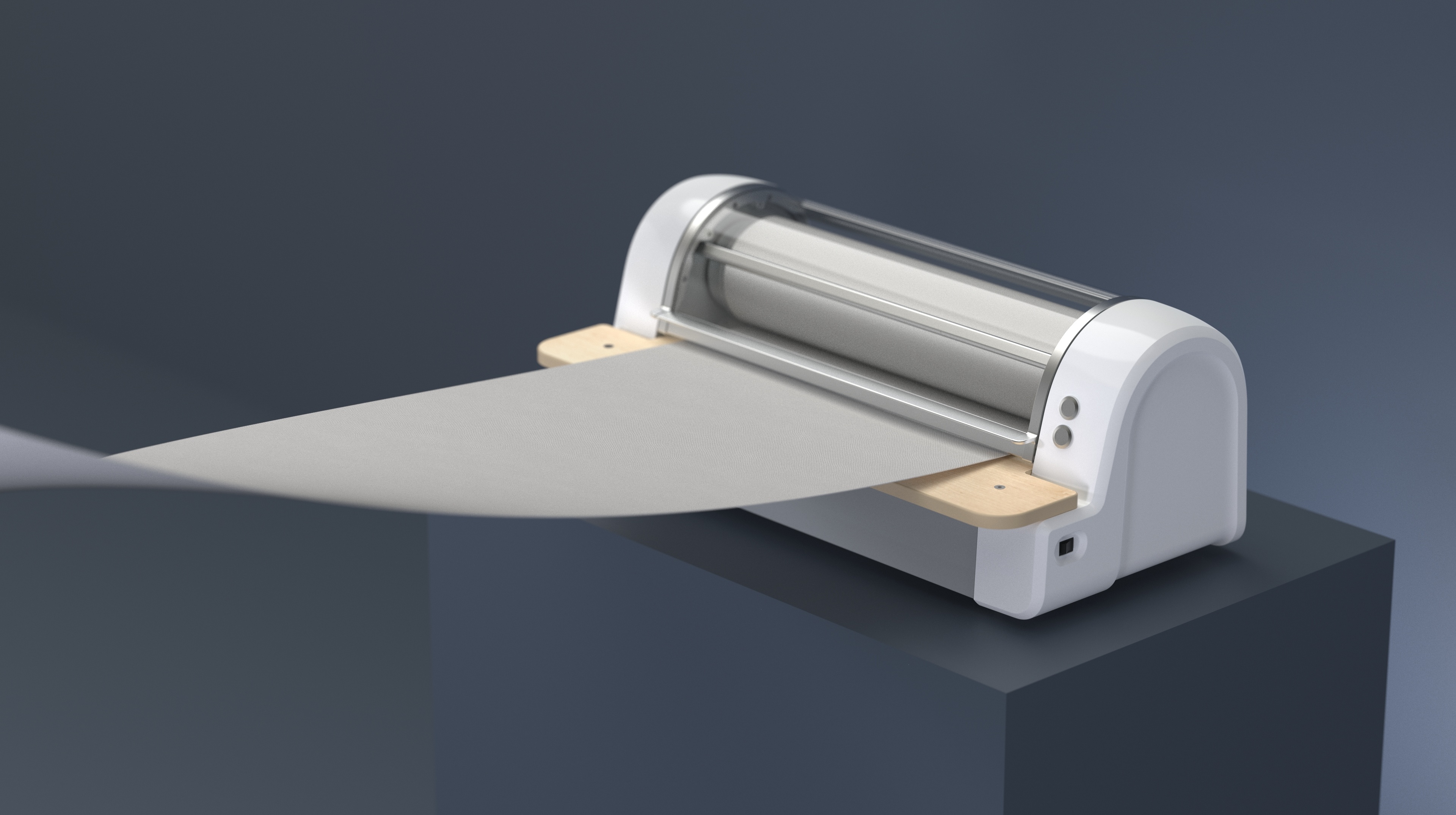

Case

Developing the mangle of the future for Pexymek

Pexymek is a Swedish company that produces cold mangles for household use. Mangling fabrics has several benefits, such as giving them longer life and less frequent need for washing. Pexymek, whose entire production takes place in Sweden, sees growing relevance for its mangle and decided to choose Semcon to develop an updated product to appeal to more users.

CustomerPexymek

IndustryIndustry

CompetencesMechanical EngineeringDesign & User ExperienceEcodesign

Background

Mangling is an old tradition in the Nordic countries. The process produces smooth tablecloths and sheets and also gives the fabrics longer life with less frequent need for washing. Mangling is popular among a small group, but the growing interest meant that Pexymek recognised the need for a modern mangle whose appeal would broaden the target group, and it chose Semcon as a partner for product development.

New design that guides the user

In terms of design, the mangle has not evolved at all over the last few decades. However, there has been a lot more activity in terms of technology, allowing both new design and functionality. Semcon and Pexymek set their sights high and wanted to develop a modern, easy-to-use mangle that customers would want to leave out on display. The mangle should appeal to both experienced and new manglers, which led to user studies and focus groups in order to understand the needs and wishes of the various target groups. The new design uses lights to guide the user and show available functions, among other things.

Sustainable and cost-effective

Pexymek produces the mangle at its site in Falkenberg, and all components are sourced from Sweden and Europe. Semcon has chosen materials and methods with a view to retaining local suppliers, which means reduced emissions from transport and a more cost-effective product.

"Producing a mangle takes skilled craftsmanship that demands manual handicraft in its construction. It should be appealing to both the touch and the eye, so we wanted an appealing, modern design with enhanced safety. We hope that this mangle will encourage more people to take up mangling and that it will contribute to increased sustainability and reduced consumption." says Emma Stenberg, CEO, Pexymek.

Focus according to Semcon’s ecodesign workshop:

Lifespan – both from a technical and aesthetic perspective. Long technical lifespan combined with a conscious timeless design.

Repairability – the technology inside the mangle has been made easily accessible to make it easier to repair and recycle.

Material choice with regard to recycled and recyclable materials.

Long lifespan combined with ease of use and intuitiveness of use provides good conditions for several generations of use.

Semcon’s delivery in the project:

Insight phase – for example, understanding existing and potential new users.

Concept phase – design, user interaction, establish electrical and mechanical concepts for the future product.

Detailed design – detailed design of the complete product and all the components included for manufacture.